Bandsaw Coils Supplier

Kogu Engineering has top-quality bandsaw coils tailored to meet your cutting needs. Our Delhi-based supplier provides a comprehensive range of durable and efficient bandsaw coils suitable for various applications. Experience precision cutting and long-lasting performance with our premium bandsaw coil solutions. Reach out to us today to find the ideal bandsaw coil for your requirements.

| Bed Size | Grades | TPI ( Teeth per inch) | |||||

|---|---|---|---|---|---|---|---|

| ( mm ) | 2/3 | 3/4 | 4/6 | 5/8 | 6/10 | 8/12 | |

| M-42 | 27 x 0.9 | * | * | * | * | * | * |

| M-42 | 34 x 1.1 | * | * | * | * | * | * |

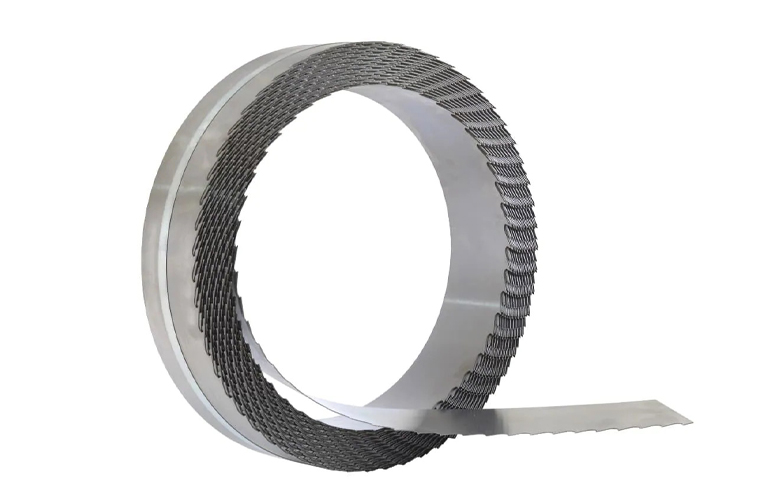

Band saw coils, also known as bandsaw coils or bandsaw blades, are continuous strips of metal specifically designed for use in band saw machines. Band saws are power tools used in woodworking, metalworking, and other industries to cut various materials such as wood, metal, plastic, and more.

The band saw coil is essentially a looped strip of metal with teeth on one edge, which allows it to cut efficiently through the material when mounted on the band saw machine. These coils are manufactured with various widths, thicknesses, and tooth configurations to suit different cutting tasks and materials.

When selecting a band saw coil, it is essential to consider the following factors:

1. Width: The width of the band saw coil determines the maximum cutting capacity of the machine. Wider coils can handle larger materials, while narrower coils are suitable for smaller workpieces.

2. Thickness: The thickness of the blade affects the precision and durability of the cut. Thicker blades are more robust and can withstand higher cutting forces, while thinner blades provide finer cuts and are suitable for more delicate materials.

3. Teeth per inch (TPI): TPI refers to the number of teeth on the blade per inch. Blades with higher TPI are suitable for cutting thinner materials, while lower TPI is better for cutting thicker materials.

4. Tooth configuration: The tooth configuration, such as hook angle and tooth shape, influences the cutting performance and finish. Different tooth styles are optimized for specific materials and cutting tasks.

5. Material: Band saw coils are made from various materials, including carbon steel, bi-metal (combining high-speed steel teeth with a flexible carbon steel body), and carbide-tipped blades (offering superior hardness and longevity). The choice of material depends on the cutting application and desired blade longevity.

When using a band saw, it is essential to ensure that the band saw coil is correctly tensioned and properly installed on the machine. Regular maintenance and proper lubrication are also crucial to prolong the life of the blade and maintain cutting performance.